For DC electromagnet, we often use low carbon steel for the core and yoke because of its low cost and high saturation magnetization. CoFe alloy has the highest saturation magnetization among ferromagnetic materials and can considered when tight space or low weight is required.

For AC electromagnet, we often use high resistance, low coercivity material for the core and yoke such as soft ferrite and powered iron. We also use laminated cores such as laminated SiFe and amorphous material for their low eddy current loss.

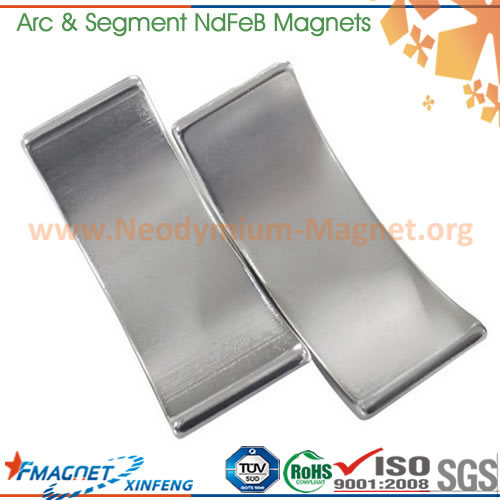

Sputtering magnetrons can be designed and manufactured using all of the major classes of magnet materials (Ceramic, NdFeB, SmCo, or Alnico). However, greater than 90% of the magnetrons we produce today are designed and constructed from the rare-earth family of magnets – Neodymium Iron Boron (Nd-Fe-B) and Samarium Cobalt (Sm-Co).